Windows let the sunshine in—which in summer means letting in the heat, as well. Radiant heat from the sun is helpful in the fall and winter, offsetting some of the energy needs to heat a building but in summer, that heat can be a problem to remove. As climate change intensifies summer heat, demand is growing for technologies to cool buildings.

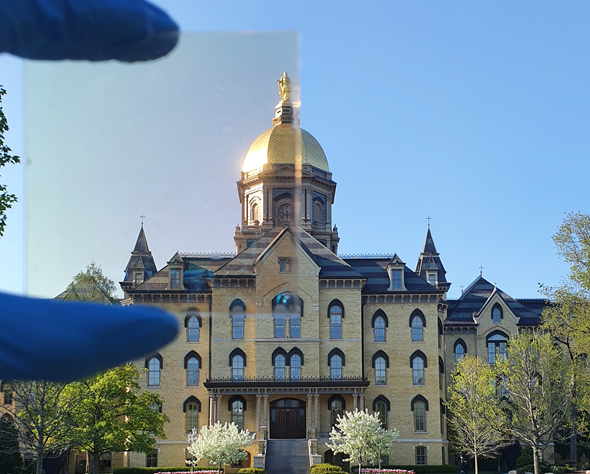

Now, researchers supported by a National Research Foundation of Korea grant funded by the Korea government and by the Notre Dame Center for Research Computing, report in a journal of the American Chemical Society that they have used advanced computing technology and artificial intelligence to design a transparent window coating that could lower the temperature inside buildings, without expending a single watt of energy.

Thermal management of buildings and automobiles is vital to achieving human comfort and energy efficiency. The energy for cooling has now reached approximately 15% of total global energy consumption. Passive radiative coolers, which do not need external energy by irradiating heat into the cold outer space as a heat sink through the so-called atmospheric window have attracted tremendous interest. As most of a building’s cooling energy is lost through windows (about 60%), efforts to develop TRC (transparent radiative coolers) that can replace conventional window materials have been seen in recent years.

However, it’s difficult to design materials that can meet these criteria simultaneously and can also transmit visible light, meaning they don’t interfere with the view. Researchers set out to design a TRC that could do just that. The team constructed computer models of TRCs consisting of alternating thin layers of common materials like silicon dioxide, silicon nitride, aluminum oxide, or titanium dioxide on a glass base, topped with a film of polydimethylsiloxane.

They optimized the type, order, and combination of layers using an iterative approach guided by machine learning and quantum computing—which stores data using subatomic particles. This computing method carries out optimization faster and better than conventional computers because it can efficiently test all possible combinations in a fraction of a second. This produced a coating design that, when fabricated, beat the performance of conventionally designed TRCs in addition to one of the best commercial heat-reduction glasses on the market. Layered thin-film photonic structures can have several advantages for TRC development given their simple planar geometry, precisely controllable dimensions, flexibility in combining different materials, and potentially scalable manufacturing.

In hot, dry cities, the researchers say, the optimized TRC could potentially reduce cooling energy consumption by 31% compared with conventional windows. They note their findings could be applied to other applications, since TRCs could also be used on car and truck windows. In addition, the group’s quantum computing-enabled optimization technique could be used to design other types of composite materials.

Want to tweet about this article? Use hashtags #construction #sustainability #infrastructure #AI #cloud #edge