Concrete is a heavy building material. Or not. When concrete is filled with air, like a balloon, it can be light weight. The AAC (autoclaved aerated concrete) is made with fine aggregates, cement, and an expansion agent that causes the fresh mixture to rise like bread dough. In fact, this type of concrete contains 80% air, according to the PCA Portland Cement Assn.)

In the factory where it is made, the material is molded and cut into precisely dimensioned units. Cured blocks or panels of AAC are joined with thin bed mortar and components can be used for walls, floors, or roofs. The lightweight material offers excellent sound and thermal insulation, and like all cement-based materials, is strong and fire resistant. AAC does require some type of applied finish, such as a polymer-modified stucco, natural or manufactured stone, or siding to maintain its durability.

Key advantages include:

Autoclaved aerated concrete combines insulation and structural capability in one material for walls, floors, and roofs. Its light weight/cellular properties make it easy to cut, shave, and shape, accept nails and screws readily, and allow it to be routed to create chases for electrical conduits and smaller diameter plumbing runs. This gives it design and construction flexibility, and the ability to make easy adjustments in the field.

Durability and dimensional stability. A cement-based material, AAC resists water, rot, mold, mildew, and insects. Units are precisely shaped and conform to tight tolerances.

Fire resistance is excellent, with eight-inch thick AAC achieving a four-hour rating (actual performance exceeds that and meets test requirements for up to eight hours). And because it is noncombustible, it will not burn or give off toxic fumes.

The light weight means that R-values for AAC are comparable to conventional frame walls, but they have higher thermal mass, provide air tightness, and as just noted, are not combustible. That light weight also gives a high sound reduction for privacy, both from outside noises and from other rooms when used as interior partition walls.

Because it is lower strength than most concrete products or systems, in load-bearing applications, it must typically be reinforced. It also requires a protective finish since the material is porous and would deteriorate if left exposed.

Building Blocks

Both blocks and panels are available. Blocks are stacked similarly to conventional masonry, but with a thin-bed mortar, and panels are stood vertically, spanning full-story heights. For structural needs, grouted, reinforced cells and beams are placed within the wall section.

Autoclaved aerated concrete offers both material and performance aspects from a sustainability perspective. On the material side, it can contain recycled materials like fly ash and rebar, which may help contribute to credits in LEED (Leadership in Energy and Environmental Design) or other green rating systems.

Further, it incorporates such a large quantity of air that it contains less raw material per volume than many other building products. From a performance perspective, the system leads to tight building envelopes. This creates an energy efficient envelope and protects against unwanted air losses.

Due to the similarity to traditional concrete masonry, autoclaved aerated concrete units (block) can be easily installed by concrete masons. Sometimes, carpenters get involved in installation. Panels are heavier due to their size and require the use of a crane for placement. Manufacturers offer training seminars, and it’s usually adequate to have one or two knowledgeable installers on small projects. Depending on the type of finish selected, they can be directly adhered or mechanically attached to the face of AAC.

Sustainability

Autoclaved aerated concrete offers both material and performance aspects from a sustainability perspective. On the material side, it can contain recycled materials like fly ash and rebar, which may help contribute to credits in LEED or other green rating systems. Further, it incorporates such a large quantity of air that it contains less raw material per volume than many other building products. From a performance perspective, the system leads to tight building envelopes. This creates an energy efficient envelope and protects against unwanted air losses.

Physical testing demonstrates heating and cooling savings of roughly 10-20% compared to conventional frame construction. In consistently cold climates, the savings may be somewhat less because this material has lower thermal mass than other types of concrete. Depending on the location of manufacturing relative to the project site, AAC may also contribute to local materials credits in some green building rating systems.

Analytics firm OG Analysis predicts crude oil price fluctuations to be a key concern for the AAC market, as fuel and chemical prices are impacting many other segments. Concerns of global economic slowdown, the impact of war in Ukraine, and the risks of stagflation are a few of the market concerns pressing the need for industry players to be more vigilant and forward-looking. Robust changes brought in by the pandemic COVID-19 in the AAC supply chain and the burgeoning drive for a cleaner and sustainable environment are leading companies to alter their strategies.

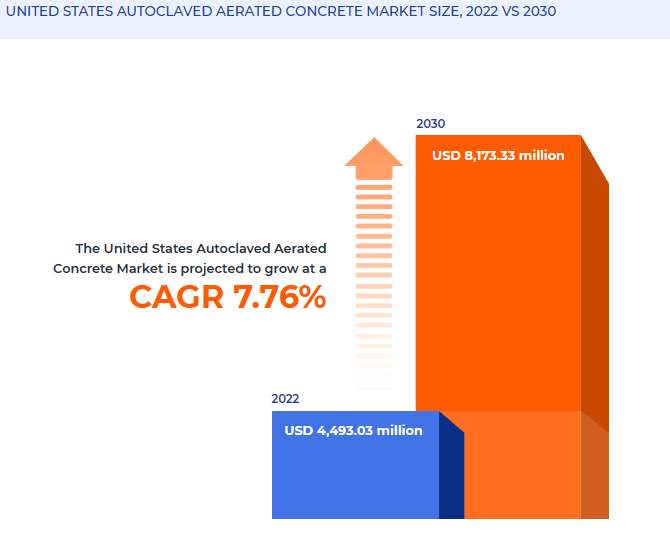

Another research company, 360iResearch, predicts the U.S. AAC market will come in at about $4.92 billion in 2023, growing to $8.17 billion by 2030. Economic development and substantial infrastructure development will impact regional revenue generation. Further, the patterns associated with domestic production, import and export, and consumption have helped market participants to analyze and capitalize on potential opportunities.

The potential effects of ongoing war and uncertainty in Eastern Europe are expected to have an adverse impact on Ukraine and reverberate harsh long-term effects on Russia. 360iResearch details the implications for demand-supply balances, pressure on pricing variants, impact on import/export and trading, and short-term recommendations to the North America AAC market considering the current update on the conflict and its global responses.

Want to tweet about this article? Use hashtags #construction #sustainability #infrastructure