“Sooner or later, everything old is new again,” Stephen King wrote. What we are seeing today is that many aspects of modern life, considered “new,” are really just the old being updated. In some cases, the old is far better than the new and is replacing today’s version.

Research has opened up unexpected ways to make the new like the old when the old has proven to be better. Material science, for example, has found the process that made Roman-era concrete so durable that, 2,000 years on, it still can support the structures that it did when new. And research into modern concrete failures has resulted in an appreciation of that Roman concrete and its composition along with a careful analysis of the reason failures happen.

In Ireland, concrete houses have been experiencing unusual failures that, in that often-inclement weather, have been determined to be caused by frost. A high proportion of the mineral mica, according to the theory, makes the building material susceptible to frost damage when its pores are filled with water. The results of analyses on the unstable concrete carried out by environmental researchers from Ulster University, Empa of Switzerland, and other experts contradicted that assumption.

The Swiss experts see the cause in another component that their Irish colleagues had not targeted. Detailed examinations of concrete samples from four affected houses showed that a mineral called pyrrhotite, consisting of iron and sulfur, is present in the building material in large proportions and apparently triggers a disastrous cascade.

When pyrrhotite in the cement paste of concrete is oxidized by exposure to oxygen, this releases sulfur which in turn leads to the formation of ettringite, a mineral formed when cement hardens. But the additional ettringite formation leads to expansion, which eventually causes cracks in the concrete.

If more sulfur is released, the mineral thaumasite is formed. This process reduces the strength of the concrete by dissolving important constituents such as calcium silicate hydrates and can ultimately result in disintegration of the building material.

Detective Work

In order to be able to clarify and prove the damage mechanisms inside this special concrete, the Empa team had to do some detective work. From conventional material analyses to complex scanning electron microscope and X-ray examinations to thermodynamic modeling was combined with meteorological data to put the common theory of frost damage caused by an excessively high mica content to the test.

Typical cracks caused by cold run parallel to the walls, while in this case they only ran vertically from the surface into the walls, often upwards from the floor to the roof. In some cases, they had even continued downward from the top, where the influence of cold is less severe. As it turned out, the meteorological data also clearly spoke against the cause being frost.

Long and severe enough cold spells that could have triggered such damage occurred too rarely in the Atlantic-influenced climate of the region. In fact, only twice: from mid-December 2009 and from November 2010 onwards. Initial damage was already evident before these frost events, and in the case of the affected houses, widening of the cracks can be observed even in summer months. They can also affect interior walls that are protected from the elements.

Conclusion: Frost plays no or at best a secondary role in the concrete damage. Although Empa experts examined samples from only four houses in detail, it is likely that the results can be generalized, as data from Irish engineers from nearly 100 affected houses showed that they also contain considerable amounts of pyrrhotite.

Roman Ash

While the Irish concrete research was underway, “across the pond” in the United States, a research project looked inside 2,000-year-old concrete made from volcanic ash, lime (baked limestone), and seawater, and has provided clues to the evolving chemistry and mineral cements that allow ancient harbor structures to withstand the stresses of time. The research has also inspired a hunt for the original recipe so that modern concrete manufacturers can do as the Romans did.

A team of researchers working at the Dept. of Energy’s Lawrence Berkeley National Laboratory used X-rays at microscopic scales to study samples of Roman concrete from an ancient pier and breakwater sites to learn more about the makeup of their mineral cements.

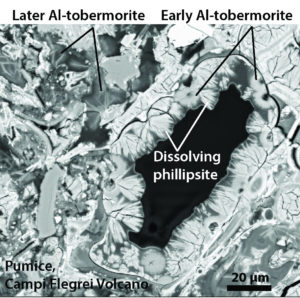

The team’s earlier work at Berkeley Lab’s Advanced Light Source, an X-ray research center known as a synchrotron, found that crystals of aluminous tobermorite, a layered mineral, played a key role in strengthening the concrete as they grew in relict lime particles. The new study is helping researchers to piece together how and where this mineral formed during the long history of the concrete structures.

The new growth of aluminous tobermorite is often associated with crystals of the mineral phillipsite. The minerals form fine fibers and plates that make the concrete more resilient and less susceptible to fracture over time. In fact, the Romans relied on the reaction of a volcanic rock mixture with seawater to produce the new mineral cements. The ancient Roman recipe is very different than the modern one for concrete.

Most modern concrete is a mix of Portland cement—limestone, sandstone, ash, chalk, iron, and clay, among other ingredients—heated to form a glassy material that is finely ground and mixed with aggregates such as sand or crushed stone that are not intended to chemically react. If reactions do occur in these aggregates, they can cause unwanted expansions in the concrete.

In order for Roman concrete recipes to gain more traction, test structures will be needed to evaluate the long-term properties of marine structures built with volcanic rock and measure how they stack up against the properties of steel-reinforced concrete, for example. Already, a growing number of concrete manufacturers are exploring the use of volcanic rock and less energy-intensive processes, which could be a win-win for industry and the environment.

Want to tweet about this article? Use hashtags #construction #sustainability #infrastructure