Congress has them, the Supreme Court has them, the White House has them—although fewer than years gone by—and everybody in Washington is looking for them. Of course, “they” are leaks. Some can be strategic, some political, others national security related; in each case, the government wants to plug the leak and prevent damage.

Builders and building owners are also on the look out for leaks, physical ones more than data or political. Leaky buildings signal dwindling energy efficiency and higher utility bills to homeowners and commercial building managers. Air that escapes from a building through windows, doors, and walls creates a drain on finances and impacts the environment. Solving the problem means pinpointing exactly where air is escaping so that cracks can be sealed—a process that can be expensive, time-consuming, and cumbersome.

The traditional method, blower door testing, might include smoke in conjunction with a blower door during which a smoke machine fills the building, and afterward, the blower machine pressurizes the building so that, from the exterior, smoke can be seen exiting through the leaks. The resulting “smoke filled room(s)” can also be a political metaphor or just a mess to clean up.

Smoke pencils can also be used in the interior, where auditors walk around in rooms to see the areas where the smoke travels to define the leakage points. Other detection techniques that have been pursued in recent years include using pulsed lasers, acoustics, ultrasound technology, and even vitamins.

Vitamins?

Researchers at the Dept. of Energy’s ORNL (Oak Ridge National Laboratory) developed a nontoxic, fluorescent air leak detection system that can find cracks in walls and roofs in existing and new buildings. Using an off-the-shelf humidifier to release a water-based solution of commercially available riboflavin, or Vitamin B2, supplement against a plywood wall with cracks, the researchers found that when the room was pressurized, tiny vitamin droplets were pulled to the leak points where they accumulated. The vitamins remained invisible unless revealed under ultraviolet light when they fluoresced.

The vitamin method has some positive benefits compared to the smoke approach. It’s ideal for occupied buildings, because the solution won’t harm furniture, for instance, plus the vitamin particles are not visible or harmful to occupants. The ORNL-developed system could be used in other spaces such as storage containers.

Researchers at ORNL didn’t stop with vitamins. A new detection system allows home energy auditors to see air leaking from a building in realtime with the help of a camera. It’s an advancement that could provide more accurate readings far more quickly than current diagnostic tools allow.

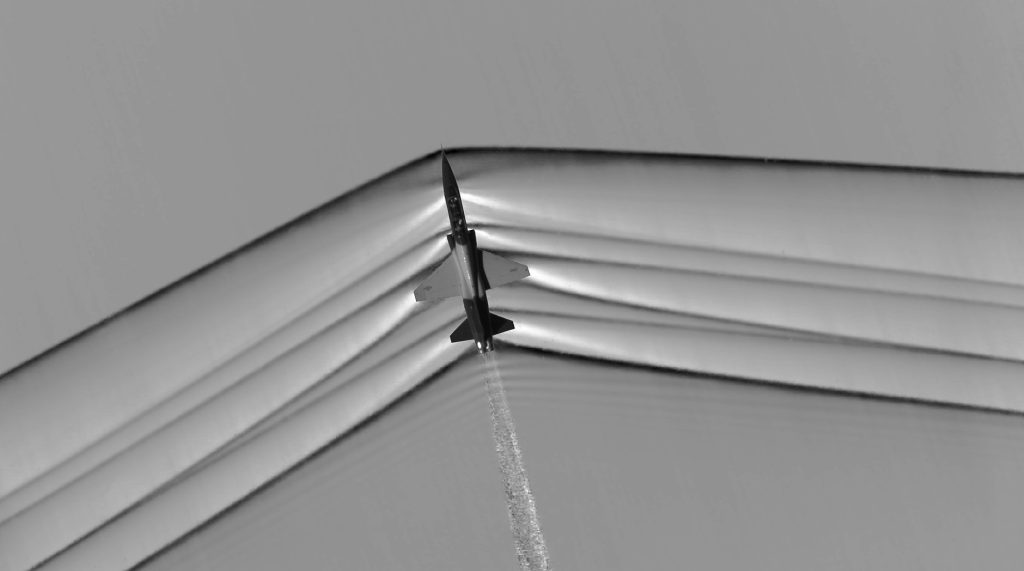

ORNL’s air leakage detection system was one of seven new technologies highlighted during the lab’s recent Technology Innovation Showcase for products close to commercialization. Based on background-oriented schlieren photography, a process used to capture fluid flow and dating back to the 1860s, it has most recently and more widely been used to photograph the flow of air around aeronautical objects in wind tunnel experiments.

The technique uses small shifts in the background of a sequence of images to visualize leaking air that has a different temperature than the surrounding air. This temperature difference creates what is referred to as a mirage when viewed in front of a building’s facade. Even though this mirage is too small to be seen with the naked eye, it can be imaged by a camera. The mirage looks just like wavy patterns you might see rising up from the pavement on a hot day or in the hot exhaust of a car tailpipe.

Detecting and Measuring

ORNL is working to ensure leaks are not just visualized but that the amount of leakage is measured, too. This will allow building owners to better prioritize areas that most need sealing. Being able to triage the biggest leaks saves time and allows for the energy reduction and carbon burden of buildings to be quickly addressed.

With almost 130 million buildings in the U.S. consuming approximately 40% of the nation’s total energy supply and 75% of its electricity, reducing energy consumption is essential as the country moves toward a clean energy future. Leakage from buildings accounts for about 4% of U.S. annual energy consumption. For residential homeowners, that amounts to hundreds of dollars a year in wasted money. And there are health impacts, too, because leaks contribute to mold that can cause respiratory issues. Leaks also decrease occupant comfort and durability of the building.

Air has multiple avenues of escape in a typical two-story single-family home with a basement. Walls, windows, and doors are obvious sources, but dryer vents, outdoor faucets, vent fans, dropped ceilings, plumbing vent stacks, crawl spaces, attic hatches, duct registers and areas where walls and floors join are also sources of air either leaking out or leaking into the structure from the outside.

The Camera Fix

By using a modest digital video camera and applying natural background-oriented schlieren photography, leaks can easily be seen from the inside or outside of the building. By using refraction, where a fluid with a different refractive index than the surrounding area is visualized based on the distortion of a background, leaks can be determined and measured.

The ORNL team applied this approach to visualize leaks through three different types of cladding—brick, vinyl siding, and CMU (concrete masonry blocks). Visualization experiments were performed under two different lighting conditions—sunny and cloudy. A small test area of cladding with a crack in the center and a ceramic heater blowing hot air through the crack served as a surrogate for the leak point. The team would experiment with the heater turned off and varying temperature ranges between the air at the exit of the crack and the surrounding air.

The visualization experiments, which was called “looking for the wiggles” in the air, showed that leaks could be detected when the temperature difference was as low as 12 to 15 degrees Celsius on the concrete block and brick claddings. Continuing work is expected to get that temperature limit down to 5 degrees Celsius.

ORNL’s leak detection research team includes Bill Partridge, Gurneesh Jatana, Singanallur Venkatakrishnan, Rui Zhang, Emishaw Iffa, Diana Hun, Flavio Chuahy, and Filipe Brandao.

Want to tweet about this article? Use hashtags #construction #sustainability #infrastructure