There was a catchy World War II saying, attributed to a submarine captain, that went, “Ship sighted, sank same.” In 2022, many construction company executives have a target in sight, meeting emissions goals, that could sink their company if they fail to meet them.

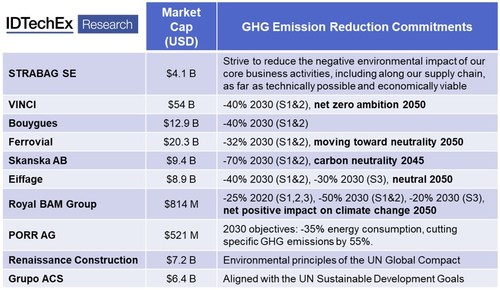

Yes, major construction firms are publishing both medium-term and long-term targets to reduce their contribution to GHG (greenhouse gas emissions), outlining their commitment to support international efforts to mitigate global climate change. Small-sized to medium-sized companies are following suit, to keep up and to met local and national mandates.

Though the CO2 (carbon dioxide) emissions from off-road construction vehicles account for only around 1.1% of global emissions, the IEA (Intl. Energy Agency) estimates that the construction industry is responsible for approximately 20% of global emissions when the production of building materials (cement, steel, glass, etc.) and infrastructure construction projects are included.

States like California are mandating the move to non-fossil fueled vehicles, hoping that the electrification of transportation will mitigate the worst of the emissions problem. Considering the environmental impact of current practices, the electrification of mobile construction machinery offers construction companies a relatively near-term opportunity to demonstrate their environmental credentials.

Primer on Emissions

Scope 1 emissions refer to direct greenhouse gas emissions from sources controlled by an organization. For example, from the combustion of diesel fuel in company machines, whether on the road or off-road. Investment in zero-emission construction machines, replacing fossil fuel-powered excavators, loaders, and cranes, will be critical to every construction company’s effort to reduce their Scope 1 emissions.

Research firm IDTechEx recently issued a report, “Electric Vehicles in Construction 2022-2042,” that forecasts the electric construction vehicle market to grow rapidly over the next decade, with a CAGR of 37.6%. This growth will come partially from incentives but mostly from executives seeing the future regulation environment will become more demanding of all to reach emissions goals.

Regulatory pressure for on-road vehicles has driven improved fuel efficiency, reduced tailpipe emissions, and is driving a market shift towards electric vehicles. The volatile gasoline and diesel fuel pricing seen in 2022 has contributed to the movement toward alternate vehicle power sources, too.

Currently, legislation for NRMM (non-road mobile machinery) is targeted at the emission of local air pollutants (such as nitrogen oxides, carbon monoxide, and particulates, but does not regulate greenhouse gas emissions. Introducing fuel consumption and carbon dioxide emission standards such as those for the heavy-duty, on-road market would be beneficial to the acceptance of zero-emission off-road machinery. However, given the considerable time it would take to update the NRMM emission standards, other mechanisms for incentivizing zero-emission machines will need to be found.

Global and Local

The 2015 Paris Agreement has seen most countries commit to reducing the emission of CO2, with many having set timelines for net zero emission (Germany 2045; UK, U.S., and Japan 2050; China 2060). To encourage the increase in zero-emission construction machines, governments must support the transition away from fossil fuels with economic incentives, including offering subsidies and tax breaks on electric machine purchases as is often the case with private cars and small trucks.

IDTechEx believes there will also be support for greener construction at a local level. Cities around the world are recognizing the impact of poor air quality on the health of their citizens and are making efforts to reduce air pollutant emissions. Implementing low emission zones in cities, where a daily fee must be paid to operate diesel machines within the zone, could greatly improve the financial viability of electric construction machines.

Oslo, the capital of Norway, is notably promoting green construction. In 2019 they established the first zero-emission urban construction site, and from 2030 onward, they will, along with six other major Norwegian cities, ban machines that don’t meet zero-emission levels from construction sites. Norway’s strong policy has spurred the development of many heavy-duty electric construction vehicle prototypes in Europe.

Improving Safety and Health

City, state, and national emissions mandates are only part of the reason to be aware of the potential in electrification of construction equipment. Of fundamental concern for construction firms should be the health of their employees. Improving worksite air quality, by eliminating diesel particulate emission, for example, is a key benefit to employee health.

Noise reduction is also a positive driver for the electrification of construction machines. Electric machines are considerably quieter than combustion engines. Bobcat, for instance, suggests that the noise level of their E10e mini excavator is around half that of a similar diesel machine with an LpA (operator noise) of 74 dB(A), about the volume of a conversation.

The construction industry is a high-risk industry for noise-related ill health, including hearing loss. Hearing protection is required on many sites, but this can hinder communication, affecting both site safety and productivity. Noise pollution is also an inconvenience for the area around building sites, and noise restrictions in urban and suburban environments limit the operational hours in which machines can operate. Zero-emission construction machines could both vastly improve the working environment and offer the potential for extended working hours.

For the full picture around this developing market, IDTechEx’s report investigates ongoing electrification work over the range of construction machine types, including excavators, wheel loaders, cranes, and telehandlers, highlighting technical and economic considerations of powertrain electrification.

Want to tweet about this article? Use hashtags #construction #sustainability #infrastructure