What is a jobsite? Obviously, it is a workplace where a project takes shape. In construction, it could be outdoors, indoors, underground, or a combination. The main components are people, materials, equipment, and tools. That combination leads to an interaction of all, and the results can be dangerous.

Safety is one of the most important aspects of a jobsite. If the workers cannot work safely, if the materials and equipment aren’t safe to use, the project, the building itself, will be much less important, especially to the workers.

As we enter a period of growing infrastructure work, safety takes on new importance. Not only are workers subjected to the normal construction dangers, but they are also interacting with outsiders driving cars, trucks, and SUVs while working on highways, or shipping containers high in the air on dock and terminal jobs. Each jobsite, therefore, presents unique dangers to the workers and a blanket “safety protocol” might not be enough, especially considering every trade has specific concerns on the job.

Top Safety Considerations

Various state and federal agencies get involved, much to the concern of the contractors who are running on tighter margins than ever. Every change order costs, every safety requirement costs, every accident costs much more.

What are the common safety concerns on a construction jobsite? Based on statistics from the U.S. Dept. of Labor and other sources, the top 10 are:

1. Falling

2. Slipping & tripping

3. Airborne & material exposure

4. Struck-by incidents

5. Excessive noise

6. Vibration-related injury

7. Scaffold-related injury

8. Electrical incidents

9. Burns

10. Material handling

At the top of this list, as usual, is falling. Falls are among the most common causes of serious work-related injuries and deaths. Fall prevention techniques can include guarding floor holes, guard rails, safety harnesses, and more.

Hearing Protection Innovation

A seldom thought of danger is noise. Much of the equipment used on a construction site generates elevated levels of noise. Prolonged exposure to loud noise can cause irreversible hearing loss in construction workers. This hearing loss could occur instantly from a single powerful explosion but occurs over time with repeated exposure to moderate noise.

OSHA cites that regular, eight-hour exposure to noise levels over 85 decibels can cause hearing damage over time. Louder noises that reach 100 decibels may cause hearing loss with just one hour of exposure each day. The following are common pieces of construction equipment and their sound levels for reference:

- Framing saw: 82 decibels

- Backhoe: 85 decibels

- Belt sander: 90 decibels

- Forklift: 93 decibels

- Nail gun: 97 decibels

- Concrete saw or electric grinder: 98 decibels

- Bulldozer: 100 decibels

- Jackhammer: 102 decibels

- Grader or scraper: 107 decibels

- Chain saw: 110 decibels

Hearing protection can help preserve hearing when always worn correctly and when these noises are present. Even with protection, there is many opportunities for exposure to detrimental noise levels on a construction site. No one wants to wear “earmuffs” all day, especially in summer heat. Ear plugs are better from the wearer’s perspective but not as good protection. Each is a tradeoff and tradeoffs are rarely satisfactory.

Indeed, hearing protection has come a long way from cotton earplugs. Doctors and audiologists have worked together to develop combination hearing protection and expansion devices. These allow workers to mute loud noises but, when necessary, communicate over the same device, or use it to enhance hearing in quiet areas.

Clear360’s next-generation wearable features 360°/3D situational awareness, precise two-way communication capabilities, and superior hearing protection from loud sounds, both continuous and transient. Custom listening modes include enhanced “super hearing” mode to detect detailed sounds in a quiet setting, speech intelligibility optimization, and even a separate listening mode for music or movies while you are passing time.

Speaking of loud noises, the explosion of costs for construction materials has many contractors screaming at their suppliers. Material that must be ordered well in advance of use to get a price advantage poses a storage problem and can add to the clutter on the site. Storing and moving materials on a construction site can become a hazard if done improperly, including both manual handling and mechanical handling with equipment.

Material Handling at the Jobsite

Manual material handling may cause injuries when workers cannot properly grasp a load or lift it, cannot see around or over the load they are carrying, cannot safely handle a load’s weight, or when repetitive motions are involved without proper form and posture.

Using equipment to move material is an obvious answer to the strains and injuries possible with manual movement. However, mechanical material handling may cause injuries when the equipment is overloaded, is loaded off-center—leading to tip overs—or when it is not positioned properly during movement.

Proper training of workers on the safety protocols of the jobsite should be a given. In fact, proper training should be available for all sectors. Many operations require not only training but certification.

Certifications

Workcred, an affiliate of the ANSI (American National Standards Institute), focuses on advancing quality workforce credentials. From 2020-2022, Workcred brought together a network of certification bodies to explore the potential for data-linking efforts to improve understanding of the value of certifications, the aggregate labor market outcomes of certifications, and insights into successful career pathways into the workforce. The network is working with the National Student Clearinghouse to match data from certification bodies, educational attainment, and enrollment data from universities, and aggregate wage data from the U.S. Census Bureau.

Despite their prevalence in the workforce, there is no complete, centralized source of data on the outcomes or impact of certifications. While there have been isolated efforts to collect this data by states, as well as self-reported data from certification bodies, outcomes data are fragmented and incomplete. By linking different data sets, the information can be used by individuals, employers, and policymakers can make more informed choices about the return on investment of certifications.

The terms certificate and certification are often used interchangeably. While this may seem like semantics, these two credentials have different meanings and significantly different outcomes. One key difference is that certificates are awarded after the completion of a learning experience from education or training courses and programs—a diploma, in effect.

A certification, on the other hand, is a third-party assessment of competence that is separate from education and training. Like getting your driver’s license, it doesn’t take into consideration how you learned to drive, just that you can drive safely and legally.

Heavy Equipment at the Jobsite

Every piece of heavy equipment on a jobsite should have a certified operator, even those that have no requirement for certification. That’s where unions and third parties can come to the rescue. The National Commission for the CCO Certification of Crane Operators), for example, has launched a new certification program for operators of concrete pumps. CCO developed this certification in response to numerous requests from industry so that users can garner the same increased safety benefits that users of other load handling equipment have seen through certification.

While not currently required by law, many large contractors have been asking for this new certification and they will be among the first ones to require their pump operators be CCO-certified. As awareness of the new program proliferates across the industry, it is expected that most jobsites will require a certified operator for not only safety reasons, but also for efficiency and professionalism.

Advanced Technology for the Jobsite

Technology can be a friend on the jobsite—or an enemy. Smartphones are everywhere and tablets and laptops are proliferating. Used properly, they are valuable for transmitting data between the site and office, delivering change orders, monitoring status, reporting safety issues, and providing immediate communications. However, they can also be a major distraction. And a distraction at the wrong time can be dangerous.

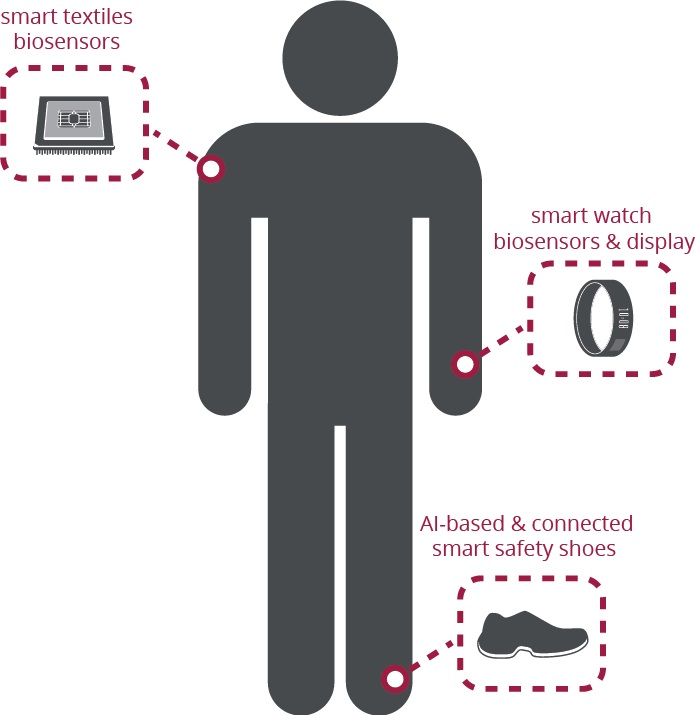

While some companies would like to reduce connected worker solutions to mobile apps available on smartphone or tablet, devices and solutions can be much more than that. Connected worker means literally “a worker connected to someone or something.” In that way, a connected worker is more than a knowledge worker. To avoid hand holding a phone, for instance, workers can be outfitted with wearable sensors that monitor and report on various safety and health conditions.

A French company, Intellinium, has been working on intelligent wearables for construction and has some interesting observations. The company started by transforming traditional safety shoes into connected safety shoes by means of a safety pod that can be attached to any (safety) shoes or boots.

The connected worker, in this scenario, has the Safety Pod on his or her shoe. Why the shoe? You always wear your shoes on the jobsite, making the shoe the best candidate to embed the connected worker hub.

But there are a few limitations:

(1) It’s very inconvenient and complex to display messages on your shoes

(2) It’s difficult to get bio-signal from your shoes

(3) Voice-enabled command and speakers are difficult to provide on shoes

For those reasons, Intellinium has been extending its efforts to other devices such as a smartwatch, T-shirt, and ear buds. The goal is to provide a full integrated smart PPE (personal protective equipment) ecosystem—but an open ecosystem based on standards—that can cover all data analytics and decision making related to worker safety, health, and security.

Again, with the expected increase in infrastructure work, safety in confined spaces, such as tunnels and underground pipes, will be in the forefront.

Confined spaces can be found in almost any work zone with people operating alone or in groups. It is not recommended to work alone in this type of environment but even group working might require some short-time solo work. Here, again, connected workers are safer if they are equipped with a bi-directional panic button, man-down, and mass emergency notification.

A Marine drill sergeant reported told his charges, “No mission is a success unless everyone comes back alive.” To paraphrase that, “No construction job is a success unless every worker goes home alive.” Safety really does have to be “Job One.”

Want to tweet about this article? Use hashtags #construction #sustainability #infrastructure #IoT #cloud #futureofwork #safety