Innovation comes at a price. Major foundations are willing to fund innovation when they see the value, regardless of the price or reward. Wells Fargo Foundation, for example, set up, with the U.S. DOE (U.S. Dept. of Energy) NREI (National Renewable Energy Laboratory), the Wells Fargo IN2 (Innovation Incubator) to fund and test renewable energy products.

Managed by NREL, IN2 recently reached a milestone: Its portfolio of startup companies raised more than $1.1 billion in external funding since joining the program. This translates to the companies raising $95 for every dollar invested in them by the Wells Fargo Foundation.

Over the past seven years, more than 60 cleantech startups have been selected for the IN2 program. The companies are provided $250,000 in non-dilutive technical assistance at Golden, Colorado-based NREL or the Donald Danforth Plant Science Center in St. Louis, Missouri. Additionally, they are introduced to an ecosystem of support including NREL’s investor network and a network of channel partners—more than 60 universities, accelerators, and incubators in the cleantech ecosystem. The companies, for their part, have added more than 1,340 jobs to the economy. This represents a total employment growth rate of 136% within the IN2 portfolio.

Buildings, both commercial and residential, account for almost three-fourths of electricity use in the United States. Newly published research suggests buildings could obtain substantial revenue by optimizing their electricity usage in just a handful of hours per year. The report considers three scenarios for 2030 which involve varying degrees of renewable energy.

The Department of Energy’s Building Technologies Office, which funded the research, recently released the National Roadmap for Grid-Interactive Efficient Buildings. This roadmap is part of the department’s goal of tripling energy efficiency and demand flexibility in residential and commercial buildings by 2030, relative to 2020 levels, and was developed in part using modeling tools developed by NREL.

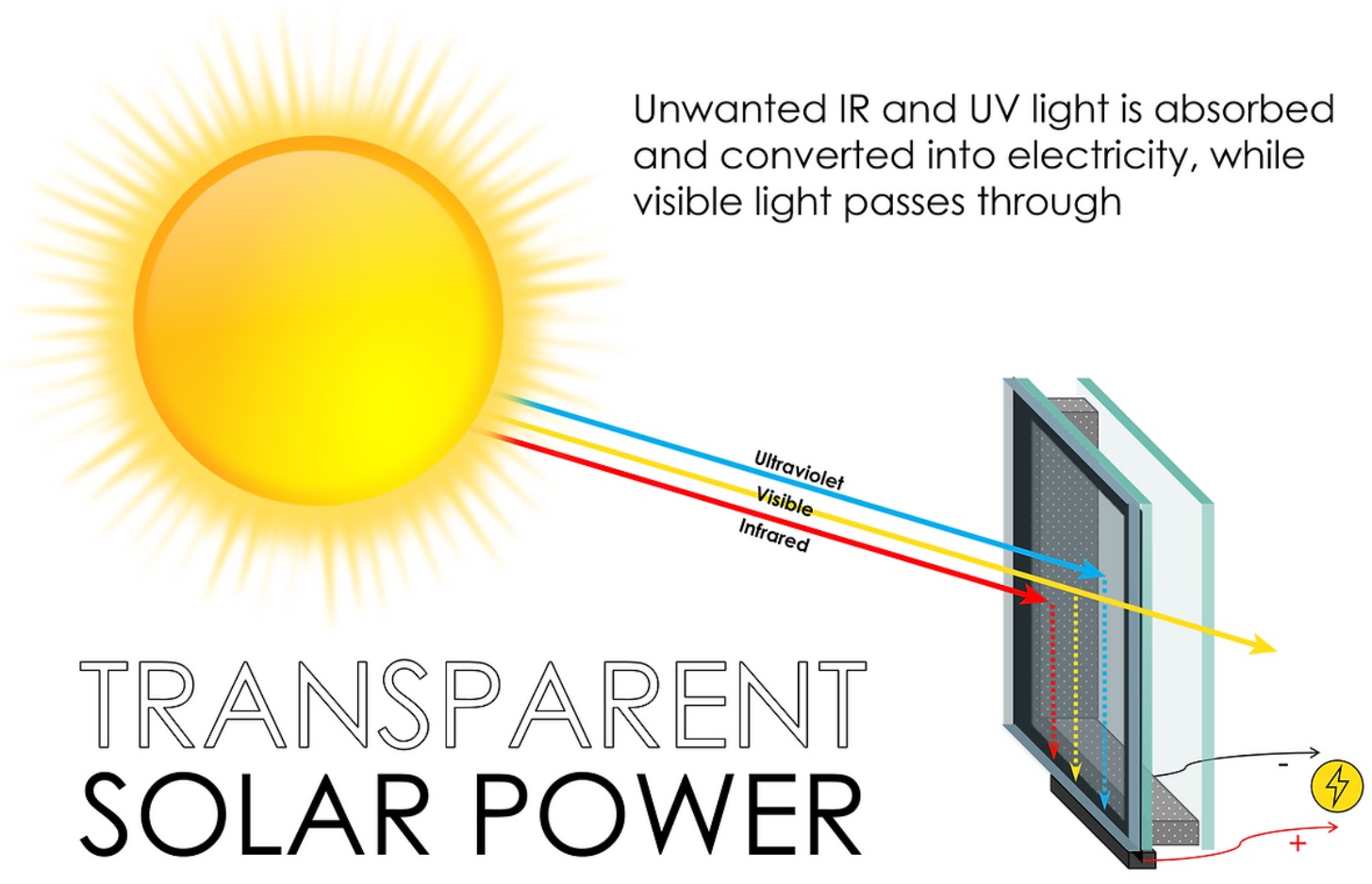

Energy is the focus of IN2 and, since solar panels are becoming ubiquitous, crowning homes, commercial buildings, and stand-alone solar farms, it’s logical that many of the projects submitted involve photovoltaics. NEXT Energy Technologies took the solar panel concept—PV (photovoltaic) electricity generation—and created a transparent coating that converts common windows into energy producing solar panel equivalents. As part of the IN2 program, NEXT transparent PV windows have completed a multi-year project comparing them to traditional commercial windows.

Results of this project are significant given that commercial buildings account for 36% of all U.S. electricity consumption at a cost of more than $190 billion annually. Additionally, windows represent 30% of a commercial building’s heating and cooling energy, costing U.S. building owners about $50 billion annually, according to DOE. Combined with the new goal of the U.S. government, achieving net-zero greenhouse gas emissions by 2050, it is imperative that the commercial real estate and construction industries transform how buildings manage energy and where they get it.

NEXT’s transparent energy harvesting technology allows architects and building owners to turn windows and glass facades into producers of low-cost, on-site, renewable energy for buildings. The photovoltaic technology is enabled by proprietary organic semiconducting materials that are earth-abundant and low-cost. This material is coated uniformly onto glass as an ink in a high-speed, low-cost, low-energy process, enabling the glass to harvest the sun’s light and convert it into electricity rather than heat.

In the IN2 NEXT project, NEXT windows were modeled and tested against traditional commercial windows, tracking performance based on their respective SHGC (Solar Heat Gain Coefficient), an industry-standard performance metric for commercial windows. SHGC measures the amount of heat – or solar gain – created by sunlight passively entering buildings through windows. Excessive solar gain can lead to overheating within a space and inefficient energy management throughout a building.

The results of the study show that NEXT’s technology could lower the SHGC from an otherwise equal window to something below .20. Achieving a SHGC below .20 while providing neutral aesthetics has been a monumental challenge for all that create vacuum deposition architectural coated glass.

The lowering of the SHGC represents a median source energy savings of approximately 10% across all locations and a maximum source energy savings of up to 50% in some locations (e.g., New Mexico, Texas, Arizona) compared to baseline scenarios for today’s traditional windows.

Speaking of New Mexico, another NREL/IN2 company is also working on energy generating windows for commercial applications. Los Alamos-based Ubiquitous Quantum Dots, or UbiQD, is turning nanoscale, three-dimensional structures — which measure about 10,000 times smaller than a human hair — into sunlight-harvesters to make solar-generating windows and plastic row covers that accelerate greenhouse plant growth.

In March, UbiQD joined with Canadian solar panel manufacturer Heliene, which operates two factories in the U.S., to integrate UbiQD’s quantum-dot film into Heliene solar panels for greenhouses. In late April, it signed a new partnership with SWM Intl, a company that makes polymer films for windows, to directly incorporate UbiQD’s quantum dots into SWM’s plastic sheets as a drop-in product for manufacturers to create solar-generating windows.

The nanoscale structures manipulate light in unique ways, absorbing it and emitting it back out in specific colors. Traditionally, they’ve been extremely expensive to make, and they’re usually composed of toxic materials. UbiQD’s product, however, is made through an alternative, inexpensive process that uses low-cost and nontoxic elements.

From the start, UbiQD set up its own production operation, now housed at a 9,000-sq.ft. facility in Los Alamos, where the company makes batches of quantum dots for sale to public and private research institutions to explore different applications, often in partnership with UbiQD. Since launching, UbiQD has prioritized development of quantum-dot-tinted windows to provide solar electric generation, potentially converting buildings into self-powering structures.

That idea is also not new but until now, most commercial development has focused on applying photovoltaic cells directly to windows, which is a more complex and expensive process. In contrast, UbiQD aims to embed quantum dots directly into the windows to absorb solar energy, and then channel the photons to solar cells attached to window frames, making the process simpler and more affordable.

The National Science Foundation has awarded UbiQD about $1.6 million in grants to develop a marketable product and, along with assistance from the National Renewable Energy Laboratory and other entities, enabled development of UbiQD’s current technology — a plastic film imbedded with quantum dots that’s fitted in between two glass panes as an “interlayer” inside the window.

In November, the company deployed quantum-dot-laden windows for the first time in three pilot projects, including a half dozen windows at NREL in Colorado, another half dozen at the Holiday Inn Express in Los Alamos, and in nearly all the windows at UbiQD’s own facility. The company is now monitoring electric output, assessing performance as sunlight changes throughout the day and during different seasons and varying weather.

Want to tweet about this article? Use hashtags #construction #sustainability #infrastructure #IoT #cloud #edge