Bridges often make it into the movies. Some bridges are so familiar, they represent the city where it is located. See the Golden Gate Bridge and San Francisco comes to mind. See the Brooklyn Bridge and you’ll be transported to New York City. And even when you don’t know the name of the bridge, it can seem familiar.

The 6th Street Viaduct, in Los Angeles, is one of those structures that appears in films and is famous to people who have never been in LA. The 6th Street Viaduct has long served as a vital connection between the Arts District on the west side of the Los Angeles River and the historic neighborhood of Boyle Heights on the east side.

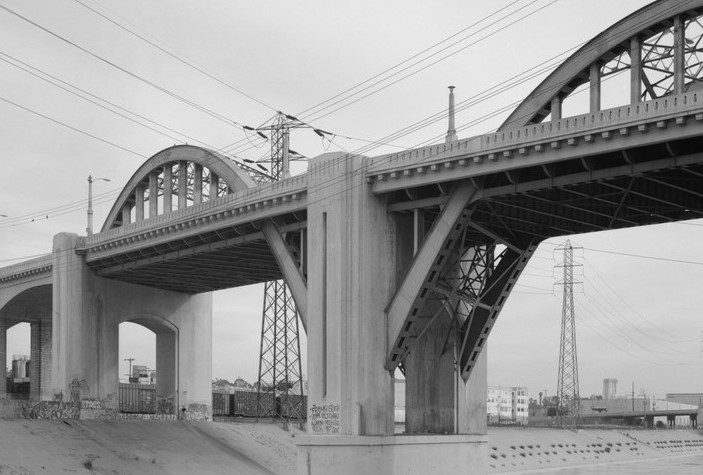

The original bridge, built in 1932, had an overall length of 3,500-ft., and extended east-west across the Los Angeles River, multiple railroad tracks, U.S. 101, and several local streets. It had a 46-foot wide, four-lane roadway with 11-foot eastbound and westbound inside traffic lanes and 12-foot outside lanes with no shoulders. There were sidewalks of varying widths on both sides.

And, of course, it was often used to represent Los Angeles’s more gritty side in countless movies, music videos, and TV commercials, including the riverbed car race in the musical Grease. In fact, more than 80 movies, television shows, music videos, and commercials were shot on or underneath the Sixth Street Viaduct each year.

Were shot there, however, is the operative phrase. The Bridge/Viaduct was demolished in 2016 following the decision to replace it due to seismic vulnerability and a rare chemical reaction in the cement supports. Due to its large size, the original viaduct was constructed using an onsite concrete mixing plant.

Unfortunately, the aggregate used in the concrete caused a chemical reaction known as Alkali Silica Reaction, which caused deterioration of the concrete structure within 20 years of its completion. Over the years, various costly restorative methods were tried in an ongoing effort to save the viaduct; all of them failed.

Seismic vulnerability studies concluded that the viaduct had a high vulnerability to failure in the event of a major earthquake, along with geometric design and safety deficiencies. Studies showed it needed to be replaced. The replacement, a $588 million project, is underway and will be the largest bridge project in the history of Los Angeles. It is funded by the Federal Highway Transportation Administration and the California Dept. of Transportation, as well as City funds.

The new bridge design was created by HNTB and Los Angeles architect Michael Maltzan. Dubbed “The Ribbon of Light,” the design features white concrete arches of varying heights canted at 9 degrees. The Sixth Street Bridge features a concrete “Y” column that branches into arches using grade 80 rebar instead of grade 60, a first for the state of California, and sliding isolation bearings exceed seismic code.

The new viaduct design is equal parts engineering and architecture and is defined by ten pairs of arches, rising and falling along the north and south edges of the bridge. These pairs of repeated concrete arches and cable supported roadway deck are simultaneously elegant and efficient. The design approach creates a unique configuration through the repeated use of arches, roadway, and pier forms: an iconic structure.

The arches incline outward from the deck and are constructed segmentally. The repetitive pier forms beneath angle outward in plan, resolving the geometries of the bridge’s inner and outer profiles. The bridge deck, suspended from the cable lattice at its perimeter, is a highly efficient, thin profile. Because the viaduct’s spans are similar, foundations at each pier are also nearly identical, further improving efficiency.

Upon completion of the new viaduct, the Bureau of Engineering will construct a 12-acre park underneath the structure that will provide access to the Los Angeles River, public art, recreational programming, and much more.

Appointed as the Erection Engineer on the project with an extensive complex structure expertise, COWI has worked closely with a joint venture of Skanska and Stacy and Witbeck to develop a constructable erection sequence, which includes step by step camber and stress analyses, and hanger installation and stressing procedure of the bridge. The current construction stage concludes with the hanger installation of the first span as well as the removal of the falsework underneath.

COWI has taken a multitude of considerations to ensure the safety of both the public and the construction crew during this complex bridge erection. This included the design of customized lock-up devices to stabilize the seismic pendulum bearings of the bridge during construction. The next step of the project is the closure of the superstructure continuity followed by the hanger installation in the second span with completion of the first of ten bridge structures planned for mid-2022.

Want to tweet about this article? Use hashtags #construction #IoT #sustainability #AI #5G #cloud #edge #futureofwork #infrastructure